-

-

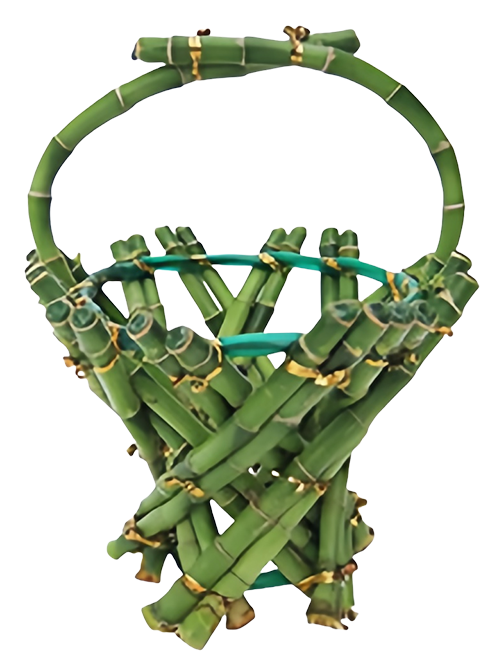

Products

Taishan Evergreen Lucky Bamboo Art Co., Ltd. is a professional lucky bamboo exporter integrating plantation, development, processing and sales. The company has so far owned two large-scale lucky bamboo planting bases with sunshades and four large-scale fi

View more

-

-

-

About Us

Taishan Evergreen Lucky Bamboo Art Co., Ltd. is a professional lucky bamboo exporter integrating plantation, development, processing and sales. The company has so far owned two large-scale lucky bamboo planting bases with sunshades and four large-scale fi

View more

-

-

-

Blog

Taishan Evergreen Lucky Bamboo Art Co., Ltd. is a professional lucky bamboo exporter integrating plantation, development, processing and sales. The company has so far owned two large-scale lucky bamboo planting bases with sunshades and four large-scale fi

View more

-

Fabricating Sequence

Fabricating Sequence

1. Leaf stripping: After entering the factory, the primitive Lucky Bamboos needs to remove their leaves immediately.

2. Cleaning: Use clean tap water to clean the stripped Lucky Bamboo stems to ensure their cleanness.

3. Cutting: According to the thickness and length of the raw materials, cut the bamboos with sharp scissors to the length required by the order. Make sure the cuts are smooth, and then sort and tie the bamboos into different bundles, each bundle consisting of 10 shoots. At this stage, the defective products should be eliminated to ensure the production quality.

4. Disinfection: Carry out strict drug disinfection, sterilization and mildew removal to ensure that bamboo branches maintain their vitality, the sequence of which is not only the key link of Lucky Bamboo processing, but also the key to the quality improvement.

5. Drying: After disinfection, put the bamboo bundles on the flat ground with foam mat or other soft materials, and air dry cuts to avoid mildew of cuts subject to dampness for long.

6. Cultivation: Sort and put bamboo bundles into plastic buckets and place them in the greenhouse for sprouting and rooting. Control the room temperature and humidity properly, and maintain indoor ventilation and proper lighting.

7. Packaging: Seal cuts with food grade wax according to customer requirements, cover the roots with plastic bags containing crystal mud, and tie them with rubber rings, and then put them into the packing box.

Lucky bamboo wholeasler in China

The largert supplier of spiral lucky bamboo in China

Professional lucky bamnoo planting, Processing and export enterprise

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Add: No.188 Dongmei Hedong Village,Haiyan Town, Taishan City, Guangdong Province, China